Corrected press release / 29 July 2022:

In paragraph 4, “negative pressure” has been replaced by “overpressure”.*

Boppard, 21.06.2022: Designed with the operator in mind: that’s how Bomag is presenting its new 37.3-ton BC 773 EB-5 soil compactor at Bauma 2022 on the outdoor exhibition area South (FS) 1009. The new machine generation is based on the most modern refuse compactor platform from the Boppard compaction experts. Handling soil compactors is particularly demanding, so they benefit from pioneering control solutions. The combination of uncompromising seating and ease of operation with intelligent control concepts guarantees highly efficient and precise work processes, greater safety on major construction sites and minimal wear and tear.

Steering, operating, accelerating and braking… the driver of the new soil compactor from Bomag has the machine literally in their grasp with two hands: all functions of the 456 hp machine can be effortlessly controlled with the joysticks on the right- and left-hand side. The operator can rest their arms comfortably on the adjustable armrests and wrap their hands around the ergonomically shaped multifunctional control levers. This eliminates the need for a steering wheel on the new BC 773 EB-5. Naturally, the engine also meets the strict requirements of EU emission stage V, Tier IV final.

The wide air-sprung high-comfort seat ensures operators have the individual support required for fatigue-free working. The spacious cabin allows maximum freedom of movement, and the full-length footrest provides optimum support for the body in difficult terrain. Thanks to its highly effective sound and vibration insulation, the cabin is transformed into an oasis of calm. Getting in and out has also been improved for greater comfort: as the roll-over protection is located behind the cabin, the door is higher, allowing the driver to enter and exit standing almost upright.

Equipped as standard with automatic heating and air conditioning, the driver’s cab remains comfortable even on hot or cold days. A modern air intake system places the cabin under slight overpressure.* An optional safety ventilation system protects against hazardous dust and gases. This prevents pollutants from entering the cabin and allows the machine to be used even on contaminated soil.

Hands on the joysticks, everything under control

Seated comfortably in the cabin, the driver can start work immediately and enjoy the best all-round visibility and clear information on the large, glare-free colour display, which is optimally positioned in the centre of the operator’s field of vision. The information system condenses the essentials, thus enabling focused work free of distractions.

Extended information is just a click away via the joystick and, thanks to the intuitive menu navigation, the driver can quickly scroll through the digital instrument display. Clear service and error messages further assist their work with concise recommendations for action – in their own language, of course.

The height of the adjustable dozer blade, the direction of travel, the lateral tilt of the machine… During demanding operations, the information and assistance system acts as a co-pilot that knows just which parameters are important. How much fuel is left in the tank, and how far will the machine get with it – useful information like this enables the driver to plan reliably at the start of the working day.

A machine that thinks for itself

The functions for automating settings are particularly convenient. For example, the machine can store blade positions such as: move forward, set dozer blade position, reverse, reset dozer blade position… Such operations can now simply be chained together and run almost by themselves. These smart assistance functions make work significantly more efficient and ultimately also ensure a consistently high compaction quality. In addition, cruise control allows the working speed to be set precisely for forward and reverse travel – almost independently of the rated speed.

No coincidence: load-bearing and even surfaces.

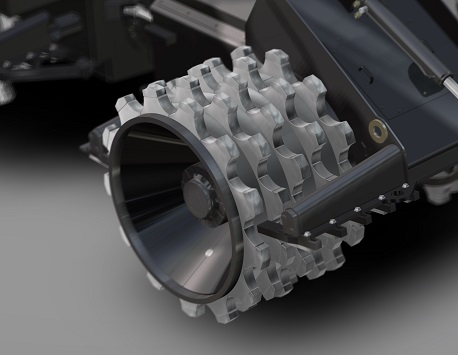

The soil compactor’s blade has been optimised for pushing and spreading soil. The tilt blade can also be angled to the right and left to allow soil to run off the sides. With its enormous thrust, the machine thus ensures maximum efficiency. Bomag’s proven compaction concept is based on wheels with rows of teeth and scrapers, ensuring consistent compaction and traction. The oscillating articulated joint ensures optimum load distribution to all 4 wheels. Thanks to wheel offset, the area is completely covered. Gaps left by the wheels are therefore fully closed during the second pass.

Wide range of applications

Whether on extensive construction sites or landfills, the new Bomag BC 773 EB-5 soil compactor can be used on almost any material, and easily masters work on very cohesive soils and in the rain.

The machine is particularly suitable for spreading and compaction on large-scale job sites. It is designed to compact mixed and cohesive soils in thin to medium layers. With a choice of compaction wheels and dozer blades, the new soil compactor can be individually adapted to the site’s requirements.

This text contains 5.066 characters (including spaces)

Press photos:

BC_773_EB-5_1.jpg / BC_773_EB-5_1a.jpg

Caption 1:

Bomag’s new BC 773 EB-5 soil compactor benefits from the pioneering platform that has already made a name for itself in refuse compaction. (Photo: Bomag)

BC_773_EB-5_2.jpg

Caption 2:

Comfort cab: air-sprung high-comfort seat with joysticks for all functions and ergonomic design for optimum all-round visibility and unobstructed blind spot check. (Photo: Bomag)

BC_773_EB-5_3.jpg

Caption 3:

Excellent operator orientation: drivers of Bomag’s new soil compactor can see everything important at a glance in the cabin. The central, glare-free colour display allows focused work and can be operated via joystick and keypad. (Photo: Bomag)

BC_773_EB-5_4.jpg / BC_773_EB-5_4a.jpg

Caption 4:

Developed with and for compaction experts: the intuitive user interface displays all the essential information on the startup view – clearly and focussed. (Photo: Bomag)

BC_773_EB-5_5.jpg

Caption 5:

Guaranteed clean and effective compaction: wheel with welded-on rows of teeth and scraper. (Photo: Bomag)