Innovations and technologies.

Based on the know-how of the experts in compaction technology. For optimum and economical work results. Quality assurance and increased construction machine efficiency through the use of digital technologies and innovative machine solutions are at the heart of BOMAG’s considerations and further developments. The goal is the networking of different construction machines and all construction phases.

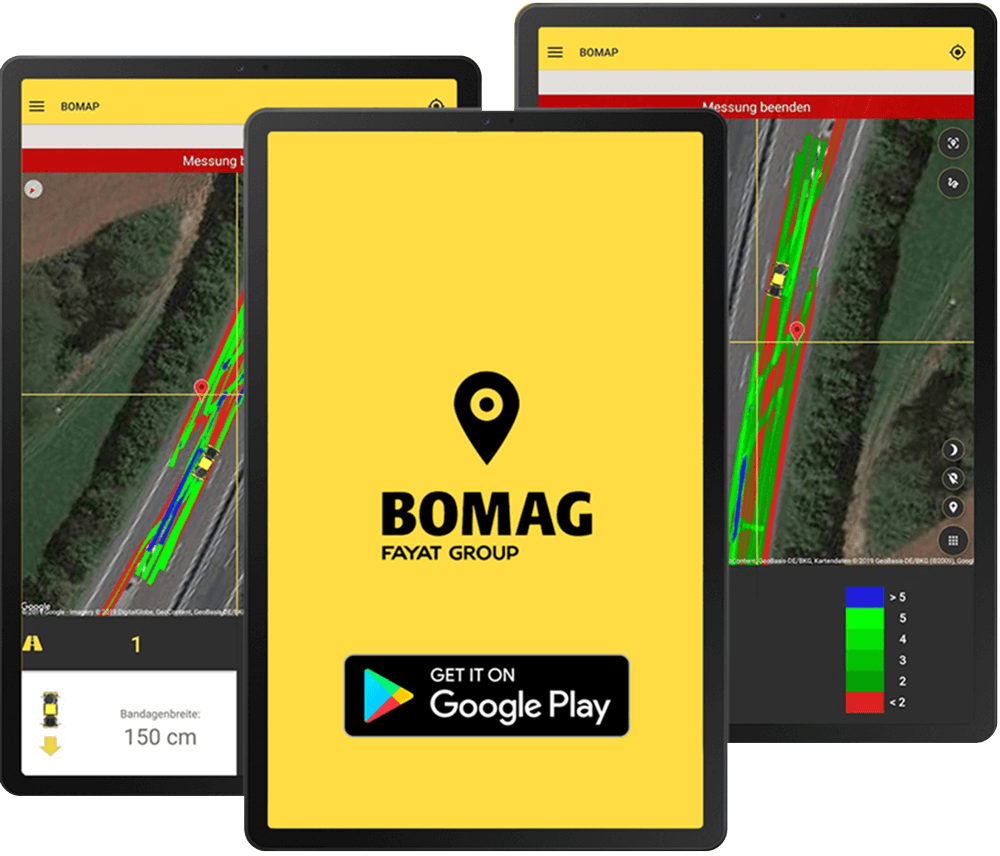

BOMAP

With BOMAP, you can monitor the results of your soil and asphalt compaction in real time, regardless of the manufacturer. The app is immediately ready for use after installation.

BOMAP draws a live compaction map of the construction site and displays the passes in real time.

Verdichtungskontrolle digital, transparent und in Echtzeit – das funktioniert ganz einfach mit der BOMAP App für Handy und Tablet.

Using BOMAP significantly reduces working time and allows fuel savings of up to 40%.

BOMAP makes Surface Covering Dynamic Compaction Control (SCDCC) very simple.

BOMAP CONNECT

ASPHALT PRO

ASPHALT PRO can be operated intuitively and used regardless of the manufacturer. The software helps to plan and optimise the entire paving process. ASPHALT PRO enables site managers to significantly reduce the planning effort for an upcoming road construction project, monitor the ongoing paving process and, if necessary, quickly take countermeasures. Access is possible at any time from anywhere: the system is cloud-based, so only requires an internet connection. The software calculates the mix requirement, communicates with the mixing plant, shows the fastest transport routes to the asphalt construction site, and passes process changes on to the mixing plant and truck drivers. It enables the efficient and smooth supply of mix and non-stop asphalt paving.

ASPHALT PRO requires no additional special hardware. The asphalt paving software solution is ready for immediate use. It stands out with its clear menu navigation and focuses on the key parameters: Temperature and mass. The paving process in quality road construction is always trackable and transparent.

ASPHALT PRO’s ingeniously simple operating concept makes integrating other BOMAG digital products easy.